Progarchives.com has always (since 2002) relied on banners ads to cover web hosting fees and all.

Please consider supporting us by giving monthly PayPal donations and help keep PA fast-loading and ad-free forever.

/PAlogo_v2.gif) |

|

Post Reply

|

Page 12> |

| Author | |

Dean

Special Collaborator

Retired Admin and Amateur Layabout Joined: May 13 2007 Location: Europe Status: Offline Points: 37575 |

Topic: Vintage (ish) Sugden Turntable... Topic: Vintage (ish) Sugden Turntable...Posted: May 02 2014 at 10:20 |

|

While clearing out a spare bedroom to make way for a work-from-home office I 'found' an old turntable that I bought back in the early 70s. This turntable was my every-day turntable for all of my teenage life and served me well, but as soon as I had enough spare money to waste on Hi-Fi it was replaced by a succession of turntables, some better, some worse, all of them costing far more than what I paid for this.

Sold in kit form, the Connoisseur BD1 was designed and made by A.R. Sugden of Brighouse (Yorkshire):  Arnold Sugden (no relation to R.E. Sugden of Sugden Audio btw) was a remarkable fellow. He left school age 14 and became an apprentice undertaker before deciding to turn to engineering. In 1953, with no formal training in mechanical or electrical engineering Sugden set about making high-fidelity turntables, tone-arms and pickups under the name of "Connoisseur" and (since this was in the days before stereo records), he also built his own disc cutting lathe for producing stereophonic microgroove discs to manufacture the records to play on the turntables he was producing. Since he didn't invent binaural discs his name has been a little forgotten in the history of stereo records and record players, (that honour goes to Alan Blumlein of EMI, but EMI never pursued the format), but it was Arnold Sugden who pioneered the use of stereo cartridges, lightweight tonearms and belt-drive turntables, long before the names we know today. So, to my little gem re-discovery. I originally bought this by happenstance, needing a decent turntable I went along to a local hif-fi specialist with the hope of buying a good quality used one but they had nothing in stock in my meagre price-range. Taking pity on me the guy suggested the BD1 and said he'd throw in a used tone-arm that he'd just taken off a brand new Thorens turntable because its owner wanted it fitted with an SME arm. So I left the shop with a small box of bits and a used but brand new Thorens TP13 tonearm, complete with cartridge. All I needed to do was make a plinth and having a carpenter for a Dad that presented no problem. The plinth in the photographs is the original that we made back in 1973, contrary to the fashion in the 70s for big chunky plinths I wanted it to be low-profile but was limited by how Mr Sugden had mounted the motor, in the end we managed to squeeze it all into a plinth that was 2¼" (57mm) high; we mounted the TP13 on an aluminium plate that was once the push-plate from an old door and fashioned the lever for the arm-lift out of an old rotary switch mechanism. Everything was direct mounted to the plinth with no isolation or suspension, I simply stood the whole thing on pieces of neoprene foam that were offcuts from making a wet suit and everything was hunky-dory.  (the eagle-eyed may spot the cigarette-burn on the plinth by the on/off switch, as I said, this turntable serve me through my teenage years, including my 3 years at university - this TT was for chilling and grooving) So there it is, looking a little worse for wear, the drive-belt is missing, the elastic bands that suspended the motor under the platter have long-since perished and the on/off knob has corroded (but that's easily remedied). The tone-arm is safely packed away elsewhere, having long-since been removed from the turntable and kept as a "spare" for my Thorens TD130 turntable that is equipped with the same arm. Out of idle curiosity I gave the 10-inch aluminium platter a flick with my finger and remarkably (considering it hadn't been used for over thirty years) it span for almost two minutes before finally coming to rest. The bearing that Sugden pioneered back in the 1960s is simple - a hardened steel spindle runs in a phosphor-bronze tube that has a single ball bearing in the bottom, this design is still used today, though Rega et al seem to favour ceramic or sapphire balls these days.The motor suspension using three elastic bands on the other-hand I think can be improved, as can the speed selection. Because this was my first turntable I've always been loathed to part with it and it always sounded great, so I am considering re-plinthing project for the summer; this time with complete decoupling between the motor, the platter and the tone arm and all the modern niceties of isolation cones and sound-absorbing foam. Sadly my Dad is no longer alive to help, but I'm sure I've picked-up enough carpentry skills to complete the task. I'm also toying with an idea of driving the motor from some custom electronics that will provide the speed selection and speed control, I haven't worked out the details of that yet, but it could involve an optical sensor to monitor the platter speed, a phase-locked-loop and a power-amp/isolation transformer set-up to drive the motor coils. I'd also consider doing something about the 10" platter but that's more complex as the drive-belt runs around the rim, however something as simple as putting a 3mm 12" acrylic mat on top could be enough. So, perhaps one day it could look like this:  Edited by Dean - May 03 2014 at 19:29 |

|

|

What?

|

|

|

|

Slartibartfast

Collaborator

Honorary Collaborator / In Memoriam Joined: April 29 2006 Location: Atlantais Status: Offline Points: 29630 |

Posted: May 02 2014 at 11:41 Posted: May 02 2014 at 11:41 |

|

I used to have a Dual that was in a real wood frame.

|

|

|

Released date are often when it it impacted you but recorded dates are when it really happened...

|

|

|

|

lazland

Prog Reviewer

Joined: October 28 2008 Location: Wales Status: Offline Points: 13619 |

Posted: May 02 2014 at 11:48 Posted: May 02 2014 at 11:48 |

|

What a great post and story!

Sounds like a fantastic project to me.

|

|

|

Enhance your life. Get down to www.lazland.org

Now also broadcasting on www.progzilla.com Every Saturday, 4.00 p.m. UK time! |

|

|

|

Dean

Special Collaborator

Retired Admin and Amateur Layabout Joined: May 13 2007 Location: Europe Status: Offline Points: 37575 |

Posted: May 03 2014 at 04:53 Posted: May 03 2014 at 04:53 |

|

@ Brian - I once owned a Dual too but I wasn't happy with it so I didn't keep it long.

@Steve - cheers, I certainly feel inspired to pursue it as I still haven't found a nice piece of timber to make an electric cello out of yet. [I have all the cello-y bits ready to go and I had a piece of willow tree slowly drying in the shed but sadly it dried too fast and split - ho-hum]. In looking into the background of the Connoisseur the more I read about Arnold Sugden the more I came to admire him - he was a "James Dyson" of his day, as well as making turntables and tonearms (with one of the earliest detachable head-shells) and the aforementioned disc cutting lathe, he manufactured pickups, stylii, microphones, electric motors, amplifiers and all the machine tools to mass produce them in a small workshop in a converted Yorkshire church. As an example of his ingenuity, in the mid-1950s he made his first stereo cartridge by mounting two mono cartridges perpendicular to each other connecting them together by a ridged wire link; while I suspect this was more a "proof of principle" rather than a serious attempt at a marketable product, he soon developed a true stereo cartridge.  |

|

|

What?

|

|

|

|

Dean

Special Collaborator

Retired Admin and Amateur Layabout Joined: May 13 2007 Location: Europe Status: Offline Points: 37575 |

Posted: May 03 2014 at 05:54 Posted: May 03 2014 at 05:54 |

|

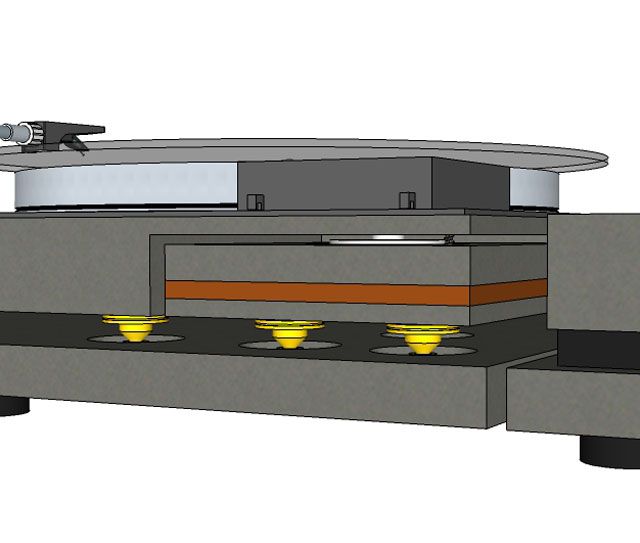

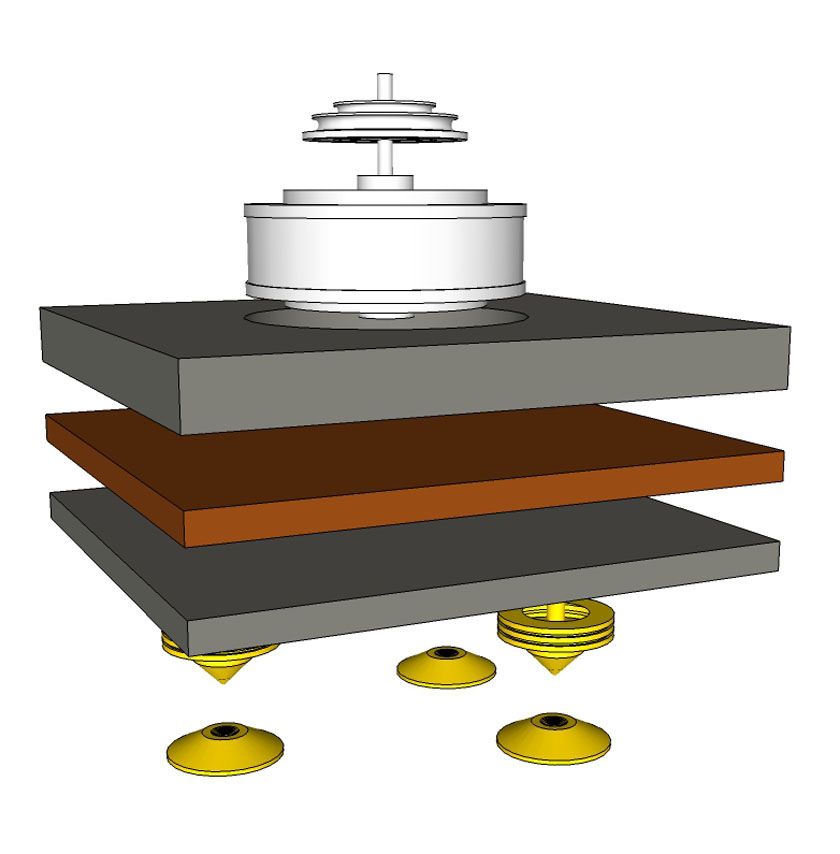

Last night (nothing on TV again after The Blacklist) I gave some more thought to the plinth design:

In this Google Sketchup picture you can see the power-supply and speed controller on the left of the main turntable base board and the motor, platter and tonearm all isolated on their own little islands. As you can see I've experimented with placing a 3mm 12" acrylic mat on the platter, not sure whether that's a good idea or not (and it's going to cost me £40 to find out). Here is a 3rd angle projection of the layout:  and view of the motor island with an exploded view of the motor mount:   I will admit that 95% of this design is purely aesthetic, I'm neither a fan nor a convert to "isolation" cones and I have used them here simply for looks. All of the true vibration isolation is achieved by the "sorbothane" foam in the motor-mount sandwich and in the feet of the base-board (which will probably be made from squash balls cut in half or something like that). The cones actually produce a coupling path for vibration, not an isolating decoupling. The purpose of cones is to transmit the vibration out of the thing producing it (in this case the motor) into something more solid and resistant (ie the base-board), which is why they are good for loudspeakers but not for turntables and CD players (or amps). Using them here for the platter and the tonearm is merely a continuation of the motor-mount support so that everything sits at the same height and to impart a degree of rigidity into the set-up. I'm in two minds over the separate island for the tone arm - again this is purely aesthetic as ideally you want a completely rigid link between the tonearm and the disc being played. The advantage of having it separate is so I can change the tonearm without having to make a completely new plinth [my original plinth is such a horrible mess because I initially mounted the TP13 incorrectly and had to move it, then later tried fitting a different arm and had to bodge the cut-out yet again]. I'm still thinking about the electronics and it all seems very do-able. The motor is an 110V AC 50Hz motor spinning at 375rpm. If I use the Sugden's 33rpm pulley I need to make this motor spin at 506.25rpm to play 45s which means driving the motor at 67.5Hz. Obviously I cannot alter the mains frequency so I will need to generate my own 50Hz and 67.5Hz signals and boost them up to 110V to drive the motor. This is a lot easier than it sounds and works out quite nicely. In doing the maths I have calculated that a simple 240V to 10V step-down transformer wired backwards will produce 110V from a 5V(rms) input. The reflected impedance of the motor calculates out at 7.6ohms so a simple 4W audio amplifier that can produce a 5V rms output into an 8ohms load is all that is needed to drive the transformer. Such an amplifier is the TDA2030A, which can be picked up from eBay for a couple of quid:  Working out how to generate a super-stable 50Hz and 67.5Hz signal is the next hurdle to overcome and I've a few ideas for that based upon generating a much higher frequency (which is easier to make stable) that is phase-locked to the platter spin-speed and then dividing it down to produce the low frequency sine-waves, but there is still some thinking to do yet before I settle on a final design. This is at the "thinking out loud" stage I'm highly receptive to all inputs... so if anyone has any thoughts, ideas, comments and suggestions I'm all ears. |

|

|

What?

|

|

|

|

Dean

Special Collaborator

Retired Admin and Amateur Layabout Joined: May 13 2007 Location: Europe Status: Offline Points: 37575 |

Posted: May 09 2014 at 18:02 Posted: May 09 2014 at 18:02 |

|

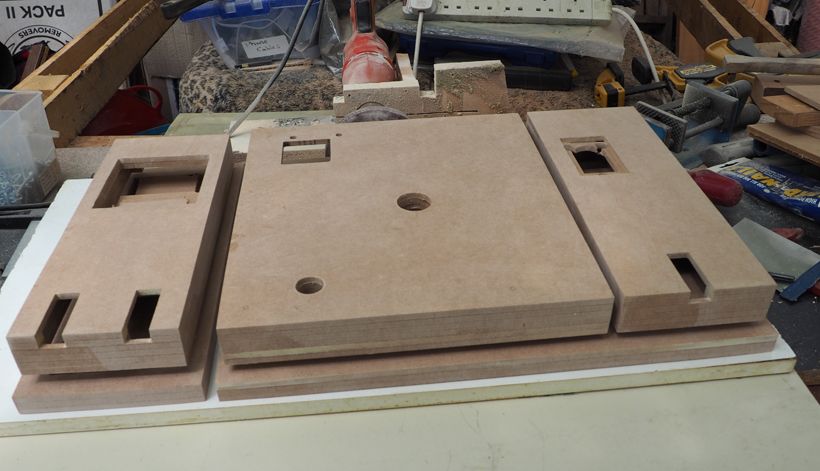

Getting close to the final design now. Added switches for the power, speed and arm raise/lower and a heat-sink for the motor-drive amplifier. I've also corrected the tonearm alignment geometry and recessed it into the plinth as it is on my TD130.  I intend to make everything from 6mm MDF sheets that will be laminated together to make the varying thicknesses of material in the design, this way I can produce recesses in the timber without using a router. It also means I can get the panels made using a laser cutter if I can find somewhere local that will do it for a reasonable price. Otherwise it will be me, a jigsaw and a dremel... that a lot of time and patience. I've more or less sorted the speed control circuitry: 331/3 rpm = [11.0592MHz Xtal] ->[Divide by 128]=(86.4KHz)->[Divide by 216]=(400Hz)->]Divide by 8]=50Hz 45 rpm = [11.0592MHz Xtal] ->[Divide by 128]=(86.4KHz)->[Divide by 160]=(540Hz)->]Divide by 8]=67.5Hz The last divider stage is a crude 3-bit DAC that converts 400Hz square waves into 50Hz sinewaves, this goes through a filter to smooth-out any rough edges and then to the power amplifier and step-up transformer. In theory that should be enough to produce a signal to drive the motor that will be significantly more stable than the mains that the old version of the turntable used. I'm working in a method of measuring the platter speed and using that as the "compare" signal in a phase-locked loop. I intended to look at using the laser diode from an old DVD drive but on taking one to pieces I spied a disc position optical sensor that is used in the Lightscribe circuitry which seems a far better proposition because it is a lot less bulky and will fit unobtrusively under the rim of the plater. This sensor will pick-up strobe marks on the underside of the platter and convert them to a square-wave. A disc spinning at 331/3 rpm does 1 full revolution in 1.8 seconds, therefore to produce a 400Hz signal that I can phase-lock to the 400Hz in the speed control circuit 400 ticks will need to pass over the sensor in one second. So in 1.8 seconds 720 ticks will pass over the sensor, which means that the ticks will be spaced every ½ degree. At first glance that seems to be very narrow, especially when you think back to the little plastic protractors we used at school that had graduations once every 1 degree:  But on an 10" platter (which has a circumference of 31.42 inches) ½ degree is 1 tick every .04" (or just over 1mm). Anyway... long explanation short - I used Excel, Gerber-viewer and Adobe Illustrator to create a 10 inch diameter disc with 720 strobe ticks and printed it on a 1200dpi printer, and it looks fine. If I could get that etched under the rim of the platter that would be even better. Edited by Dean - May 09 2014 at 18:08 |

|

|

What?

|

|

|

|

yam yam

Collaborator

Crossover Team Joined: June 16 2011 Location: Kerberos Status: Offline Points: 6313 |

Posted: May 09 2014 at 20:59 Posted: May 09 2014 at 20:59 |

|

LOL! My first 'hi-fi' turntable was also a Connoisseur BD1.

|

|

|

|

Dean

Special Collaborator

Retired Admin and Amateur Layabout Joined: May 13 2007 Location: Europe Status: Offline Points: 37575 |

Posted: June 17 2014 at 14:34 Posted: June 17 2014 at 14:34 |

|

^ I genuinely don't have a preference either way - Vinyl, CDs, mp3s - as long as the music's good and everything sounds clean and loud I'm going to be as happy as a pig in very comfy chair. That we can get music out of scratches on a disc of PVC, using nothing more than a pin and a cone of paper is magic enough, converting that simple mechanical transformation into electrical signals and back again is a piece of cake by comparison.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ Brief update. The project is moving along, albeit slower than I would have hoped. The idea of laser cutting was quickly discarded once I'd calculated how much it was going to cost to cut three 1.2m sheets of 6mm MDF, so I crudely bolted a Rotozip Rebel spiral saw to an old wardrobe door to form a cheap and cheerful router table so I could accurately cut-out the dozens of pieces of wood needed to make the plinth. They are all glued-up now and waiting to be sanded, filled and sanded again before painting. I've "Macgyvered" a simple sanding table using the same wardrobe door as before but now fitted with an electric drill and a hook'n'loop sanding disc pad - just waiting on a delivery of sanding discs from Amazon before work can continue. I'm also toying with the idea of making a pantograph attachment for a Dremell so I can engrave legends on the three switches, and perhaps a snazzy logo on the plinth itself, but that's a scary prospect because one slip and it's goodnight Vienna to weeks of work. Next stage is to produce the brass boxes that house all the electronics - aluminium would probably be easier to work with but I can't braze that and brass leaves me the option of polishing and varnishing it, which could look cool (or it could look really tacky). I've bread-boarded most of the electronics and that seems to work as planned, in the end I used the TDA2030A in BTL configuration because the size of step-up transformer I just happened to have lying around in a drawer - if I wasn't such a tight-wad I'd have splashed out on a toroidal transformer of the right turns-ratio, but this works just fine. The electronics for the "soft-touch" switches works and I really like the piano-key style lever switches I've designed - since the Connoisseur is piece of a late-60s/early-70s design I wanted the switches to resemble the keys on an old cassette player yet still look modern. I've still got the arm-lift to sort-out as I want that to be operated by a "soft-touch" switch too - it will probably be based upon those cheap plastic servos that are used in R/C toys even though the control circuitry for those is more complicated than it really needs to be just to pull on the Bowden cable that operates the Thorens arm-lift. My dear wife has come-up with a brilliant idea for the 3mm acrylic mat that I wanted to use to increase the size of platter from 10 to 12 inches - no clues or spoilers as to what that idea is until I post pictures of the finished TT.  That's about it so far. ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ Being an Engineer by trade and being equipped with an engineer-type mind means that when I take something apart it's because I want to know how it works, and how it was made, and more importantly, how it goes back together. It also means that I'm plagued by NIH syndrome (Not Invented Here Syndrome) - this results in seeing how something works and immediately wanting to fix, improve or simply change it to make it different. If you've ever wondered why designs keep changing it's more often than not NIH-S in action. 20 years ago I built a test jig and wrote some software to test a video amplifier, we still make and sell that video amp and over the years its been handed over to different engineers and technicians to maintain and look after - every one of them has re-written the test software, not because it didn't work or was buggy, but simply because of NIH-S. So, since starting this little project I've had dozens of ideas running around in my head that I'd like to have tried but decided that I wanted to keep as much of the original Arnold Sugden Connoisseur hardware as I could. The only thing I've discarded so far is the on-off switch and three perished elastic bands so it will still be able to carry the Connoisseur badge with some degree of integrity. Therefore ideas of replacing/upgrading the motor were put to one side, along with thoughts of replacing the bearing, the drive pulley and the 10" platter, because if I'd done all that then the only original thing left would have been the metal platform itself ... and to be honest I'd quite like to have replaced that too with one that was the full-width of the plinth. The outcome of all that is, once this is finished (and it will get finished) I'd quite like to design and build a brand new turntable from scratch. I would also like to make my own tonearm even if the precision required is probably beyond the my metalworking capabilities and that of my poorly equipped garden shed workshop - but the physics, mathematics and geometry behind their design isn't hard. When you see what little "engineering" goes into a Rega, Linn, VPI, Pro-ject or Music Hall turntable the idea of building one yourself doesn't seem such a challenge - with turntables and tonearms it doesn't take a genius to see that less is more. Edited by Dean - June 17 2014 at 14:37 |

|

|

What?

|

|

|

|

Finnforest

Special Collaborator

Honorary Collaborator Joined: February 03 2007 Location: The Heartland Status: Offline Points: 16913 |

Posted: July 24 2014 at 18:29 Posted: July 24 2014 at 18:29 |

|

Dean, thought you might enjoy.....Tonight just might be one of those nights...

|

|

|

|

Dean

Special Collaborator

Retired Admin and Amateur Layabout Joined: May 13 2007 Location: Europe Status: Offline Points: 37575 |

Posted: July 24 2014 at 19:36 Posted: July 24 2014 at 19:36 |

|

Oh My - a Garrard auto-changer... with an 8-track.

While on vacation last week we dropped in on a friend of Debs who'd just retired and moved down to Somerset. While they were Debs friends I'd never actually met her husband before, after showing us around their new house he took us to a room above his garage which was going to be his new "man cave" that he was kitting out as a listening room with all new equipment (which had only been delivered the previous day and was still boxed and unopened). Rather than show me the expensive audiophile contents of the boxes he instead pulled a sturdy and very professional looking flight-case from behind the sofa. "Would you like to see my retirement present from work?" he asked. Puzzled but curious, I nodded.... this was inside:  ..that's a Limited Edition Technics SL-1200GLD Direct Drive Turntable. *gulp* ... a $2,500 retirement present - somehow I don't think I'll be getting anything like that when I retire. I glanced around the room for his record collection but couldn't see anything so assumed it was all still boxed up after his move. To make conversation I told him I'd just bought the 180gm 40th anniversary Dark Side of the Moon. "I've got an older version of that" he said -- I replied that I had several copies, including a first edition. He didn't look impressed. He opened a cupboard to reveal his entire album collection ... of around 10 albums (I didn't count them) and most of them were hifi test albums, so it was my turn to look unimpressed. Until that is he reached in and very carefully pulled his copy of Dark Side ... a 1978 original half-speed master recording from Mobile Fidelity Sound Lab ...only 25,000 of those were ever produced and they are said to sound amazing. For all the very expensive equipment in that room, including the SL-1200, I would have happily walked out of there with that under my arm.

|

|

|

What?

|

|

|

|

Catcher10

Forum Senior Member

VIP Member Joined: December 23 2009 Location: Emerald City Status: Offline Points: 17835 |

Posted: July 24 2014 at 19:49 Posted: July 24 2014 at 19:49 |

|

I have seen a few of these custom built tables, this one the plinth from a slice of mesquite root ball.

The builder had to let the slice dry for about 18 months. Tonearm is a LAD, similar to Jelco arms, LAD was produced in Wales and to my knowledge they no longer are in business. He used a Marantz 6300 motor, isolation feet from a Technics I think. Some nice CNC work on this table for motor base and knobs and such...for sure a pc of eye-candy. Rather cool looking too..

Enjoy your build Dean. |

|

|

|

|

|

Finnforest

Special Collaborator

Honorary Collaborator Joined: February 03 2007 Location: The Heartland Status: Offline Points: 16913 |

Posted: July 24 2014 at 19:54 Posted: July 24 2014 at 19:54 |

|

^^Holy cow.....so when do we knock over his place? I'll grab the album you can drive the getaway....

My first turntable was a Technics but it didn't look anything like that....I remember the Mobile Fidelity stuff. Had a few albums, and I think I still have a couple CDs. "Tea for the Tillerman" comes to mind. Edited by Finnforest - July 24 2014 at 19:55 |

|

|

|

Finnforest

Special Collaborator

Honorary Collaborator Joined: February 03 2007 Location: The Heartland Status: Offline Points: 16913 |

Posted: July 24 2014 at 20:03 Posted: July 24 2014 at 20:03 |

|

Oh I like that one too Jose. If I keep following this thread I'm gonna want an album collection again. Not good since I gave away all my vinyl!

|

|

|

|

Dean

Special Collaborator

Retired Admin and Amateur Layabout Joined: May 13 2007 Location: Europe Status: Offline Points: 37575 |

Posted: July 24 2014 at 22:18 Posted: July 24 2014 at 22:18 |

I agree that it is very nicely made but it's not to my tastes. I think we're going to have to acknowledge that our ideas of cool in the turntable world are wildly different.

|

|

|

What?

|

|

|

|

manfromstoke

Forum Newbie

Joined: August 11 2014 Location: United Kingdom Status: Offline Points: 13 |

Posted: August 12 2014 at 07:52 Posted: August 12 2014 at 07:52 |

|

To say I'm impressed would be a understatement. Be great to hear and see the end result. What an interesting chap Arnold Sugden was!

Still have a passion for HiFi born from listening to my parents all in one system comprising Garrad 301, leak valve amp mounted inside a walnut cabinet and if memory serves the inbuilt speakers were GEC. Things moved along and like many I did the HiFi trail of Dual 505, Rega2 ,Thorens TD150 and then eventually got bit by the 'Graduated increments of pitch with respect to time brigade', thus became a disciple of Linn. Had a long period of HiFi abstinence from about 1998-2010 but now enjoying the system once more. For me nothing can quite match the ritual of picking up that black round thing placing it on the platter and lowering the arm while watching that cantilever take the strain. Reading your thought process leads me to believe the end result could be something special. Please keep us updated.

|

|

|

A fool can ask more questions than a wise man can answer.

|

|

|

|

Dean

Special Collaborator

Retired Admin and Amateur Layabout Joined: May 13 2007 Location: Europe Status: Offline Points: 37575 |

Posted: August 12 2014 at 11:36 Posted: August 12 2014 at 11:36 |

|

Thanks for the words of encouragement Nee. The build is progressing, albeit slowly, I hardly seem to have any spare time to work on it of late. The woodwork had its first coat of paint at the weekend (a rather dark shade of moody blue) - that's got to be sanded, inspected, retouched and painted again before copious coats of clear varnish are applied. It will then sanded and buffed to a mirror finish before I'm going to be happy with it. As I said, a lot of this is going to be about the aesthetics - this has got to look better than good - so I'm having to reign-in my normal impatience to see the finished turntable in action to get it just as I want it. I'll post some work-in-progress pics when I've got something worth showing.

|

|

|

What?

|

|

|

|

progbethyname

Forum Senior Member

Joined: July 30 2012 Location: HiFi Headmania Status: Offline Points: 7849 |

Posted: August 20 2014 at 11:05 Posted: August 20 2014 at 11:05 |

This is a great story, Dean. Thank you. Pretty interesting. All that gear with only one desirable record...pretty damn good one at that. |

|

|

Gimmie my headphones now!!! 🎧🤣

|

|

|

|

Gerinski

Prog Reviewer

Joined: February 10 2010 Location: Barcelona Spain Status: Offline Points: 5154 |

Posted: August 22 2014 at 01:29 Posted: August 22 2014 at 01:29 |

|

Congratulations Dean with this exciting project!

I'm no engineer but the only thing which looks a bit weird, as you have yourself pointed out, is having the arm mounted in a separate body than the platter. Both will need to be joined in some precise manner in order to preserve the alignment. I understand the argument about having the possibility to change the arm type without having to screw the body top, but what about simply having a sub-top for the arm in the same body as the platter, which could be replaced if necessary by a different one?

|

|

|

|

Dean

Special Collaborator

Retired Admin and Amateur Layabout Joined: May 13 2007 Location: Europe Status: Offline Points: 37575 |

Posted: August 22 2014 at 05:50 Posted: August 22 2014 at 05:50 |

Having the tonearm separate is a common feature of high-end turntables:  While there is no direct connection between the pivotal point of the tonearm and the spindle of the platter the weight of both plinths acting through the spikes should be enough to ensure a degree of rigidity between them. If the vibration in both is kept to a minimum then the complete decoupling should not present a problem, (given the wavelength of acoustic vibration is measured in metres not millimetres any residual vibration is sympathetic anyway). I can always add weight to reduce vibration and increase rigidity. The obvious advantage is the geometry can be adjusted which is something that is difficult to achieve on a one-piece plinth, while I took measurements from my Thorens TD160 to get the approximate position of the arm, I cannot claim my measurements were in any way accurate so some tweaking will be necessary. But as I said, from the perspective of this design it's purely aesthetic. |

|

|

What?

|

|

|

|

Dean

Special Collaborator

Retired Admin and Amateur Layabout Joined: May 13 2007 Location: Europe Status: Offline Points: 37575 |

Posted: October 27 2014 at 04:48 Posted: October 27 2014 at 04:48 |

|

Quick update...

Long way to go yet, progress has been incredibly slow due to other priorities, such as The Good Lady deciding that, since The Daughter is getting married next year, the entire house inside needs completely redecorating, and the garden needs sorting out, and the patio, and the car-port/veranda, and probably much more besides, (it's been a while since I consulted the extensive 2-page "to do list" that appeared on the 'fridge door several months ago). Quite why this should be is beyond my simple male-mind to comprehend, but she has spoken... So... Back in June the woodwork looked like this:  And now, after receiving multiple coats of paint it looks a little like this:  This is just a "dry-fit" of all the major parts to ensure it all fits together nicely. The paintwork will require more sanding and several coats of clear lacquer before being buffed to a mirror finish, then a coat of anti-static because at the moment it attracts dust and cat-hair like crazy. I've still got all the metalwork to do and I've yet to transfer all the breadboarded electronics to PCB but hopefully those can be accomplished over the winter-months. Onwards and upwards.

Edited by Dean - October 27 2014 at 04:53 |

|

|

What?

|

|

|

|

Post Reply

|

Page 12> |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |